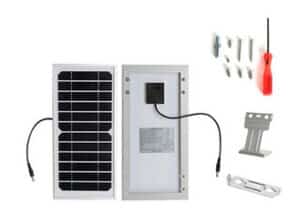

Want to manufacture your product? Here, you can find top-quality materials and advanced engineering to make it a reality.OEM/ODM manufacturing starts with the best materials. Find the best sheet metal, plastics, and spinning in the market at the best prices. With our top engineering, you can find what you need for your OEM/ODM.